The Wood Innovation and Design Centre

The Wood Innovation and Design Centre in downtown Prince George features inventive use of wood solutions to solve every-day design and construction challenges, while demonstrating the beauty and diversity of value-added BC wood products. The construction system used is repeatable and expandable to other building types and sizes.

As Canada’s Green University, UNBC is excited to attract world leaders to Northern British Columbia and to Prince George, a centre of Canada’s forest industry. This region is comprised of many communities that are reliant on the forest and the forest industry; the building is a showcase of innovative uses of wood that will lead to community sustainability and resiliency.

WIDC is the home of the Master of Engineering in Integrated Wood Design program. During the year-long program, students pursue research on wood and other forest products related to future wood structures. Graduates will lead the world in the construction of new wood structures that will be both sustainable and healthy, illustrating the benefits of wood construction to healthy ecosystems and healthy communities.

Construction of the Wood Innovation and Design Centre

Building with Wood

One of the many benefits of new wood construction is the speed and accuracy of erection of the building.

One of the many benefits of new wood construction is the speed and accuracy of erection of the building. Why Build with Wood?

- Wood is renewable - Wood grows naturally and helps reduce our environmental footprint

- Wood meets code - Advanced technology and modern building codes are expanding the opportunities for wood in construction.

- Wood is versatile - Wood’s design flexibility allows a wide range of building types and applications - both structural and aesthetic.

- Engineered wood is innovative, adaptable, and efficient.

- For more information on B.C. forests and products, visit www.naturallywood.com

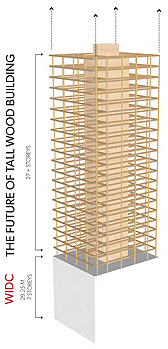

The Future of Tall Wood

Inventive use of wood solutions to solve every day design and construction challenges will demonstrate the beauty and diversity of value-added B.C. wood products. In this way, the team intends to use the building to tell a story that ultimately sells more wood and enhances the B.C. forestry and wood manufacturing economy. Great stories add value, and connect the project to both the history and future of wood technology.

Inventive use of wood solutions to solve every day design and construction challenges will demonstrate the beauty and diversity of value-added B.C. wood products. In this way, the team intends to use the building to tell a story that ultimately sells more wood and enhances the B.C. forestry and wood manufacturing economy. Great stories add value, and connect the project to both the history and future of wood technology.

Instead of focusing solely on a showpiece structure, the team instead created a building that is easily replicated. This was a fundamental choice, made in the interest of seeing many more architects, engineers, and private developers recognize the value of the design as a cost-effective competitor to steel and concrete. This is the best way to ensure that the B.C. wood economy grows - through repeatable, meaningful innovation.

Download high resolution image

Wood Structures Comparable in Scale to the Wood Innovation & Design Centre

The Beauty and Story of Wood

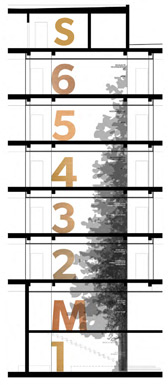

The massing of the building is simple and restrained, allowing the beauty of wood to shine through. The 4671 sq.m building stands almost as tall as B.C. forests, and made up of 1846 m of wood. The building envelope design is a metaphor for bark peeling away from the trunk; bark on the north side, thick and protective from the cold and elements thins towards the south sunlight.

The exterior is more opaque to the north and becomes increasingly transparent as one circles the building to the south. This optimizes sun exposure and insulation, tuning the building’s energy performance to the orientation and northern climate. As the building transforms from opaque to transparent, it does so with a rational logic: in northern climates most heat is lost to the north. To the east and west, the wood wind columns supporting the curtain wall glazing cut the low angle of the rising and setting sun as the facade becomes more transparent. To the south, maximum transparency welcomes passive solar heat gain. In summer, heat gain is controlled with interior wood blinds.

CLT

GLULAM

LVL

Construction Timeline

Fall 2013

- Cross-laminated timber (CLT) elevator core in place

- Glued laminated timber (Glulam) columns set in place, continuous from concrete floor slab to roof

- Glulam timber beams installed to help stabilize columns and core

- Remaining timber beams set in place. CLT floor panels begin to stagger on first few levels, further stabilizing the structure. These CLT floor panels (two panel thicknesses - 5 and 7 layers of dimensioned lumber) stagger to accommodate services.

- Remaining CLT floor panels are installed. Main starcase has been installed, made of laminated veneer lumber (LVL)

Spring 2014

- Building envelope, with LVL window mullions and roof + penthouse enclose the building so that interior finishes may be protected during installation

- Interior finishes and exterior envolope complete, comprised of charred wood panels, yellow cedar boards, and red-stained wood for the canopies and interior feature wall.

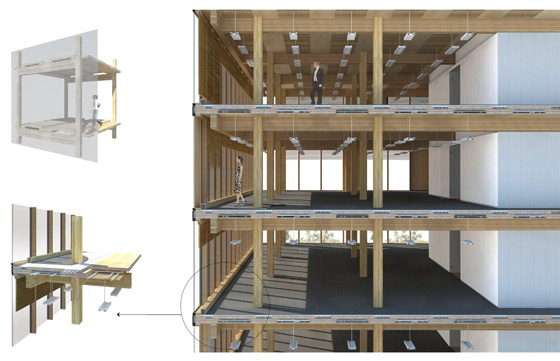

Innovative & Repeatable Structural Systems

With the staggered floor slab design, the distribution of mechanical and electrical systems throughout the building is solved in a new and repeatable way. Horizontal chases are created between the staggered timber slabs in order to run services both below the floor and above the ceiling. An acoustic subfloor system is loose-laid over the chases, providing convenient access to these areas. Lighting and fire suppression systems are run in the ceiling recesses, concealed with a simple, removable wood-slat finish.

With the staggered floor slab design, the distribution of mechanical and electrical systems throughout the building is solved in a new and repeatable way. Horizontal chases are created between the staggered timber slabs in order to run services both below the floor and above the ceiling. An acoustic subfloor system is loose-laid over the chases, providing convenient access to these areas. Lighting and fire suppression systems are run in the ceiling recesses, concealed with a simple, removable wood-slat finish.A B.C. Building for the Prince George Community

Mechanical Contractor

Prince George, B.C.

Cross-Laminated Timber Supplier

Penticton, B.C.

New & Innovative Western Red Cedar Products

Port Alberni, B.C.

Site Services Contractor

Prince George, B.C.

Foundation Concrete Contractor

Prince George, B.C.

Electrical Contractor

Prince George, B.C.

Structural Insulated Panel System Supplier

Penticton, B.C.

Wood Structure Installer

Merritt, B.C.

Elevator Contractor

Prince George, B.C.

Laminated Veneer Lumber Supplier

Brisco, B.C.

Curtain Wall Contractor

Vancouver, B.C.

Roofing

Prince George, B.C.

Reinforcing Steel Contractor

Prince George, B.C.

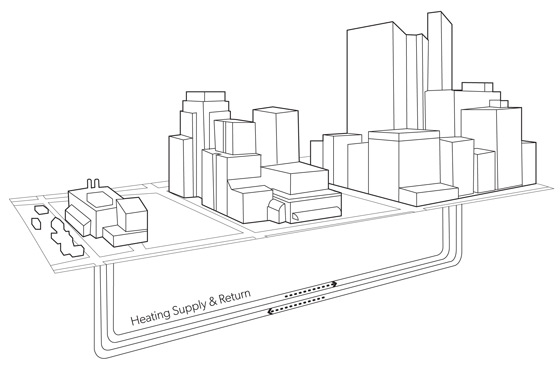

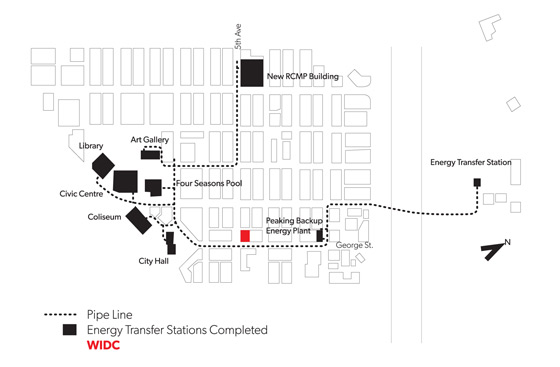

The District Energy System of Prince George

Contact

Wood Innovation and Design Centre

499 George Street - 3rd Floor

Prince George, British Columbia

V2L 1R5 Canada

250-960-5241

meng@unbc.ca