Personal protective equipment must be selected with informed intentionality, not based on convenience. The MSDS is an effective means of identifying necessary personal protective equipment. However, specific testing may be required to quantify the potential for harm. In addition, manufacturers of safety equipment also provide specifications for use of their products.

Lab Jackets

Lab jackets are commonly made from a blend of polyester and cotton. Polyester provides excellent wear and liquid shedding properties; however, it is also quite flammable. Fire resistant cotton and Nomex lab jackets are available. If working with open flames, pyrophoric materials, strong oxidizers, or high-hazard techniques, a flame resistant lab jacket is required. In general, a good lab jacket has knitted cuffs to reduce contamination of the cuff and snaps for quick removal.

Here are come additional resources for selecting a lab jacket:

- Flame test of polyester/cotton blend lab jacket (video)

- Flame test of various clothings and lab jackets (video)

- Discussion regarding lab coats (blog post)

Cleaning lab jackets: Lab jackets should be cleaned once per semester, at a minimum, and monthly or weekly, depending on the materials handled. An industrial cleaning service should be used to avoid contaminating personal washing equipment. Lab jacket cleaning is available through Chemstores.

Gloves

Gloves come in an array of styles and materials. Glove choice should always be checked against the MSDS and the glove manufacturers recommendations (i.e., glove thickness, glove composition, type of exposure). Here are some glove manufacturers' chemical resistance guides:

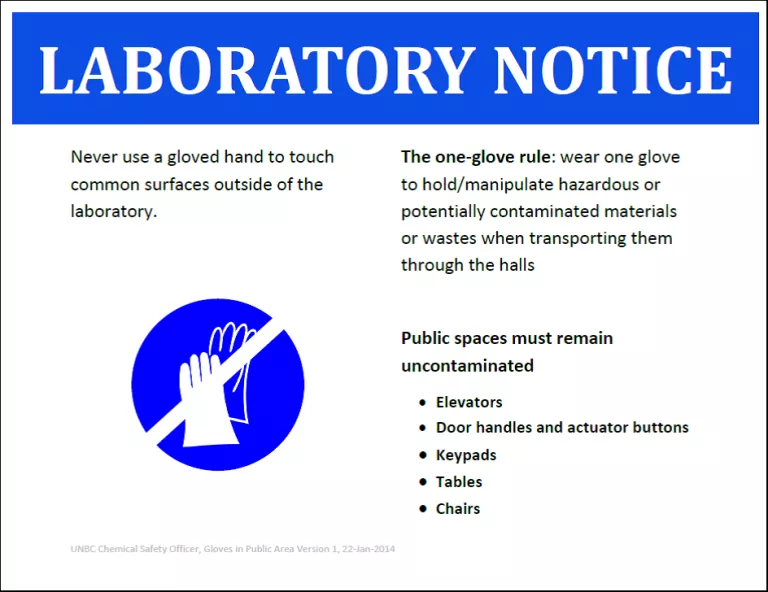

One glove rule: Gloves are not intended for use in public areas. If a chemicals or laboratory materials are carried through a public area, one hand must be kept glove-free for manipulating door handles and elevator buttons.

Safety Glasses, Safety Goggles, and Faceshields:

A variety of different styles of eye protection are available through Chemstores. Safety glasses are the minimum required eye protection in an active wet lab. Safety glasses must be Z87.1 compliant. If safety glasses do not appear to be effective due to splashing or the type of work performed, safety goggles are required. For work above head height, with large quantities, or with reactive or pressurized systems, a face shield should be worn as well.

Fit: Safety glasses need to fit comfortably to ensure regular use. If you keep forgetting to take off your safety glasses, you are wearing a well-fit pair and much more likely to use them.

Over The Glasses (OTG): Prescription glasses do not provide sufficient eye protection to replace safety glasses or goggles. OTG safety glasses are designed to fit over most prescription glasses and provide an accessible and affordable alternative to prescription safety glasses.

Respirator/Airway Protection:

Fumehoods provide a primary means of airway protection that surpasses most respirator masks. Whenever possible, a fumehood should be utilized as first defence against chemical exposure; however, there are situations that will require the use of a respirator mask. The MSDS and WorkSafetBC guidelines should be checked to determine if a respirator mask is necessary.

Fit Testing: Fit testing is required on a yearly basis for situations requiring respiratory protection (potential to exceed WorkSafe BC occupational exposure limits).